Can Several 12-volt Chargers Be Safely Used on an EV's Battery Pack?The answer is "yes, as long as the chargers are isolated." But what does this mean? An isolated charger is one in which the output is not connected (or connectable) in any way to that of another charger. That means there can be no direct connection between the battery leads and the AC input plug or the case of the charger. What kind of charger would be unisolated? One would be a charger that used an autotransformer instead of a transformer with a primary and secondary. An autotransformer has only one winding, and gives reduced or increased voltage by using taps on that winding. Autotransformers are sometimes used where the voltage change needed is relatively small, and there is no need for current multiplication (since there's only one winding, the entire winding has to be sized to the higher current). It would be very surprising indeed to find an autotransformer in a 12-volt battery charger, where the voltage reduction is 10:1. Another would be if there were no transformer at all, but the voltage reduction were instead accomplished with a PWM circuit. Again you're most likely to see this where the output voltage is relatively close to the input voltage. This is the way those inexpensive 1000 watt 230-to-115 volt European power converters work. There are indeed some road EV chargers which also work this way -- for example, the Bohn chargers, and the K&W BC-20. In such a charger, the battery isn't isolated from the AC mains, so using two of them can be big trouble. (On the other hand, you can use ~one~ of them with another isolated charger.) All of these unisolated road-EV chargers are high-voltage output, from perhaps 72 to 120 volts, and unsuited to use as 12-volt chargers. I have never seen a commercial 12-volt charger which wasn't isolated. However, it's not difficult to test a charger for isolation:

|

|

|

|

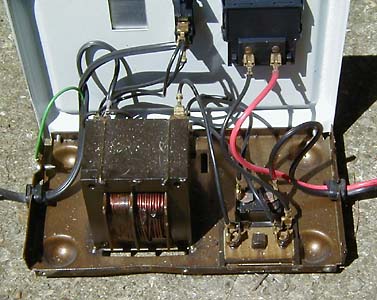

This Schauer, about 15-20 years old, is a 100% manual charger. It consists of just a transformer,

full-wave rectifier, ammeter, and circuit breaker. There's also a switch to change transformer

taps for either 6 or 12 volt output. The rectifier is at the lower right. It appears to be bolted to the chassis, but is in fact fastened to a metal plate, which is in turn set in a plastic mount to isolate it from the case. My ohmmeter measures infinite resistance from the output connectors to case.

|

|

|

|

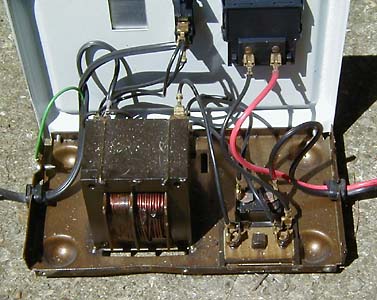

This Dayton charger is similar to the Schauer above (I suspect they were manufactured by the

same company), but it has a rudimentary charge controller. The rectifier mounting is identical

to the Schauer's, but has an additional heatsink rising vertically for the charge regulator. This

is also isolated from the case; note that it's about 10mm from the rear panel.

|

|

|

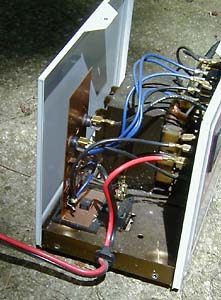

Here is a Century brand charger, with a bit more automatic sophistication than the Dayton above. Its charge controller and rectifier dissipate heat into the heatsinks shown at the top of the photo, right behind the front panel, and at the right. Note that the corner of the heatsink at right has been bent up to prevent contact with the case -- evidence of sloppy assembly. This heatsink is in fact still unsettlingly close to touching the case; there is at most 3mm of clearance when the case is closed. |